I am embarrassed to admit how much blind trust I put into a helmet without truly understanding if the “certification” label attached to one has any merit. Who is making sure helmets are actually effective? The manufacturer? The Government?

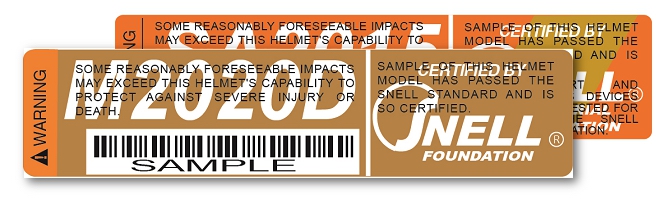

There are several types of certifications for modern helmets. The Snell Foundation tests dozens of different types of helmets based on their intended use, including Motorcycling, Elite Automotive Sports, Kart, SA Automotive Sports, Equestrian, Skiing, and Cycling. Snell certification is considered the gold standard for helmet testing and is recognized by every major racing organization.

I am not an expert in helmets or traumatic brain injuries; I am a consumer like most of you. I also want to be clear: this article is simply to provide a starting point for the understanding of who the Snell Foundation is and what that certification means. For more detailed information on the actual testing process, please see our Complete Guide to the Snell M2020 Standard. Knowing this, let’s go for a deep dive into helmet certification—specifically Snell certification.

Who Is Snell?

But like many great undertakings that advance society, Snell began as a response to a tragedy. In 1956, during an SCCA race, popular amateur racer William “Pete” Snell died when his car crashed and the helmet he wore failed to protect him. In response, the Snell Memorial Foundation was created and has been dedicated exclusively to head protection through scientific and medical research, standards development, helmet testing, and public education.

See Also: Ultimate Guide to Motorcycle Helmets

A Not for Profit Helmet Safety Organization

My partner in life happens to be an attorney (specifically, a medical malpractice litigator). She advocates for plaintiffs and has taught me repeatedly how money and self-interest can lead to lower standards and loss of integrity. Without integrity, there can be no trust. Hence why the basic tenets of “not-for-profit,” and “no manufacturer representation on the board” which are the core of Snell, mean so much to the consumer.

But wait there’s more! To ensure that Snell does not become complacent in their testing lab operations, they open the doors for inspection by another recognized authority. A2LA is a globally recognized authority in charge of quality laboratory accreditation programs.

Since 1997, the Snell Foundation’s California laboratory has been approved for helmet testing by the American Association for Laboratory Accreditation (A2LA). The accreditation confirms that the Foundation’s California laboratory is capable of performing Snell testing and has the necessary quality control to ensure the accuracy and validity of Snell test results.

What Are the Other Helmet Certifications Besides Snell?

Time to unleash the confusion! At least that is my first reaction to researching all the other certifications that get applied to motorcycle helmets, but I promise to keep this as simple as possible.

Who are the main players you ask? There are really 5 main certifications for helmets that apply globally and cover the most significant portion of products available to consumers. Besides the current Snell M2020 there are also DOT, ECE, FIM, and SHARP.

Obviously, manufacturers want to sell to the largest marketplace possible, which is why we have many of the same products available across the globe and why we see multiple certifications labeled on a helmet. Each standard has its own unique requirements, and while they are unique, there is certainly overlap in requirements—but this does not mean passing one certification equals passing another.

DOT FMVSS-218

The most basic standard—and it applies only in North America. The DOT does not test and approve helmets. The DOT sets standards, and it is up to each helmet manufacturer to certify that their helmets meet the DOT standard. It is up to you to decide if that satisfies your needs.

ECE 22.05

Still the European minimum, and it has acceptance in many countries around the world, including 47 in Europe, and Canada. The 22-05 standard is in process of being phased out in favour of a much improved 22-06.

Many current helmets are already meeting 22-06 and it will be the only ECE standard when 22-05 is removed come January 2024. This makes the ECE 22-06 the most up-to-date legal requirement for motorcycle helmets intended for public road use in the 47 countries that follow ECE standards. Most Canadian provinces accept DOT or ECE certification.

See Also: DOT vs. ECE Helmet Safety Standards

FIM Certification

Developed for the requirements of competitive motorcycle riding. It is an indicator of a very high level of head protection, and that is reflected in the cost of FIM Certified helmets. Many tracks will accept Snell and/or FIM certification; you need to confirm with the track you plan to race before going.

SHARP

SHARP is a great resource, and despite being funded by the UK government, it is widely recognized for quality testing and valuable research. A worthwhile way to compare helmets to each other because of the star rating (more on that in the next section).

How Does Snell Compare to Other Helmet Safety Certifications?

The Snell Process

|

|

Snell differentiates itself from other certifications primarily because it is a voluntary testing process, with no affiliations to industry or Governments. While the Snell tests do not affect what is legal to sell, a Snell test proves that a helmet goes beyond the usual standard and offers excellent protection.

Snell states the following:

Four of the most critical elements affecting a helmet’s protective properties are:

- Impact management: how well the helmet protects against collisions with large objects.

- Helmet positional stability: whether the helmet will be in place, on the head, when it’s needed.

- Retention system strength: whether the chin straps are sufficiently strong to hold the helmet throughout a head impact.

- Extent of protection: the area of the head protected by the helmet.

During impact testing, Snell strikes a helmet against different surfaces of varying sizes and shapes. Snell conducts a roll-off test, designed to simulate if the helmet will stay on a rider’s head as they tumble. During a Snell test, both the chin strap and the chin bar face stress tests focused on how much stretch or deflection they may exhibit during extreme forces. Snell abuses the outer shell with sharp and pointed objects to determine if they can reach a rider’s head. Helmets need to withstand solvents and chemicals commonly associated with motorsports.

Possibly my favorite test by Snell is for the face shield. Snell testing fires a pellet from an air rifle at the face shield to see if it penetrates. The face shield must be able to stop a lead pellet traveling at 500 kilometers per hour.

See Also: The Best Full Face Helmets You Can Buy in 2022

DOT and ECE

The DOT (Department of Transportation) standard FMVSS-218 and the ECE (Economic Commission of Europe) standard 22.05 are legally minimal acceptable standards for Motorcycle helmets. The simplified explanation is that in order for a helmet to be sold in these regions as a “Motorcycle Helmet” it must pass these requirements.

Of course, there are nuances to all this. Not every country in Europe adheres to things the exact same way, but if your helmet meets ECE 22.05 or higher, you can pretty much wear it on a motorcycle anywhere in Europe and be legal.

In North America, the DOT FMVSS-218 standard is required for a Motorcycle helmet to be considered legally compliant for road use. Naturally, the USA has its own oddities, the first being that not every state has an actual helmet law. This makes me wonder if every brain should be legal for road use?

Second, novelty helmets “not intended for motorcycle use” (think really small half helmets), can be sold on shelves right next to DOT approved helmets, potentially confusing consumers—and this is totally fine too.

To be “legal” for use on the road in most states in the USA a helmet must meet the DOT FMVSS-218 standard. The Canadian government basically looks at the DOT and ECE labeling and accepts that as a “Legal’ minimum on Canadian roads.

The Basics of DOT

To qualify for DOT certification, a helmet must pass four separate tests:

- An impact test

- A penetration test

- A retention strap test

- A peripheral vision test

While these tests are difficult to pass, the requirements are less stringent than for some other motorcycle helmet certificates. So why is DOT not always favorably looked upon? DOT helmets are actually tested by the manufacturers and if the manufacturer claims they pass, they can use the label.

The Basics of ECE

ECE requirements follow the same 4 requirements as the DOT, but step it up a bit by adding:

- Chemical testing

- UV testing

The ECE penetration test assesses multiple areas of the helmet shell, and the chin guard has its own test to pass as well. The ECE will test multiple helmets from different production runs and also tests the face shield for durability.

SHARP Certification

This is a test/certification from the United Kingdom. The British government funds SHARP testing, and in order for a helmet to be tested, it must already have an ECE certification.

SHARP does not give a pass or fail but instead gives 1 to 5 stars. This provides consumers with the ability to compare approved helmets with testing that factors in different speeds, rotational elements, and differently shaped impacts.

FIM (International Motorcycling Federation)

This is the only actual racing certification and applies to full-face helmets only.

The FIM decided to impose its own certification in 2019 to ensure that all of its racers received the same level of protection, regardless of who sponsored their gear. The FIM is the governing body for a vast range of Powersports disciplines including MotoGP, Supermoto, Motocross, and many many more.

The FIM standard came about because they believe DOT and ECE standards are grossly inconsistent and, in many cases, obsolete. As a racing body interested in protecting its athletes, it wanted to make sure its standard matches the circumstances.

The most obvious difference between the FIM’s tests and those of the other agencies is speed. High-speed impacts have been tested in FIM-certified helmets. The FIM tests impact in a variety of ways. The shell and EPS foam core of a helmet is tested for linear and oblique impacts, which occur when the force of the impact is distributed unevenly. Not all crashes are created equal; not all head impacts occur at the same angle, and that’s where the FIM’s tests are superior.

What Influence Does Snell Have?

Because Snell is a non-profit, independent organization that provides voluntary testing of helmets, consumers gain a higher degree of confidence that a helmet with this certification will provide a higher level of protection for the head and brain, over minimum government standards.

By acting as a research platform providing unbiased testing, helmet manufacturers gain valuable insight on how to improve their products. As brain/head injury science evolves, manufacturers continue to push forward with technology that can meet consumer demand. Independent testing like Snell provides manufacturer guidance through proven failure and elevates consumer confidence in the brand names that choose to submit products for scrutiny.

Motorsports organizations of all types have vocalized their support for the Snell Foundation. The American Motorcyclist Association (AMA), FIM (International Motorcycling Federation), NASCAR, and the FIA all recognize Snell Certification.

Is Snell the Best Certification Standard?

Helmet safety is constantly changing trying to stay current with research and help elevate the way we measure protective abilities. Snell is another tool consumers can use to help evaluate what products will best suit their riding needs.

Snell updates standards at least every five years based on new research findings and available technology. Changes with ECE standards are also evolving. Helmets are already meeting the ECE 22.06 standard, which represents a significant advance from the prior 22.05 standard. I only highlighted the 5 major certifications most prominently related to Motorcycle riding. These are not the only testing bodies available.

Snell is certainly a better indicator of a helmet’s ability to provide head protection, over just DOT/ECE. It is also valuable information to know that currently there are only a handful of open-face helmets and no modular helmets that have a Snell certification. Does this mean they are unsafe? Not at all, it simply means that they cannot meet the bar Snell testing sets.

This Writer’s Opinion on Snell Certification

A Snell Foundation Certification is the most broadly recognized independent testing for motorcycle helmets. It is supported heavily across the Motorsports world and provides confidence that a helmet meets a much higher threshold of head protection than just a DOT sticker. The testing process is constantly evolving and Snell, while not always perfect in the eyes of some, is still very much a good indication to the consumer about a helmet’s protective qualities.

Trying to rank which of these certifications is best—well, I find that misguided. When it comes to helmet safety, all of these certifications are seeking the same goal: keeping riders safe by reducing TBI’s.

The testing process is constantly evolving, as can be seen with the new ECE 22-06 standard. FIM provides unique testing focused on the speeds and energies of a racing environment. For example, SHARP is very useful when wanting to see how different helmets stack up against each other.

It simply makes sense to take in as much information as possible when making a purchasing decision about riding gear, particularly a helmet. Read the labels, find out what certifications and standards your helmet complies with, then get out and enjoy riding with additional peace of mind.